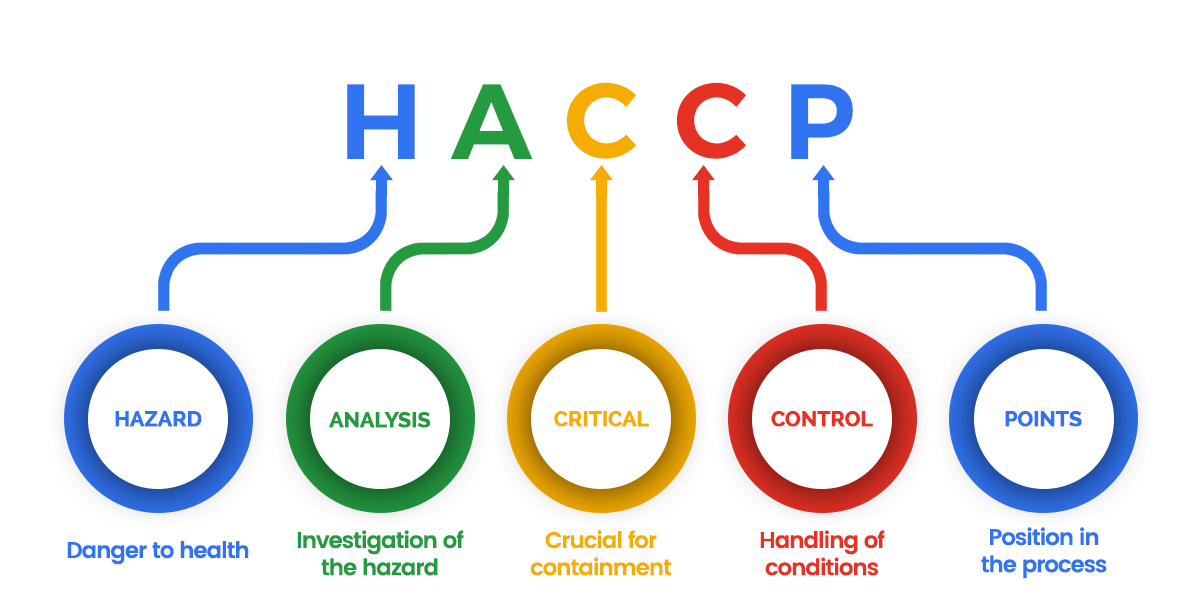

Hazard Analysis

Critical Control Point

The Hazard Analysis and Critical Control Point (HACCP) system is a preventative approach to food safety. It is used in the food industry to identify and assess potential hazards in the food production process and put controls in place to minimize the risks of these hazards.

HACCP is a proactive approach to food safety that can be applied to any food production process. It is a preventative system that is used to identify and assess potential hazards in the food production process and put controls in place to minimise the risks of these hazards. The HACCP system is an international food safety certification that is recognized globally.

The HACCP system is

based on seven principles:

- Hazard Analysis: identify potential hazards in the production process.

- Critical Control Points: identify and assess the control points in the production process where the hazards can be controlled.

- Establishing Critical Limits: establish acceptable limits for the identified hazards.

- Monitoring Procedures: establish procedures to monitor the critical control points.

- Corrective Actions: establish procedures to correct any deviations from the critical limits.

- Verification Procedures: establish procedures to verify that the corrective actions are effective.

- Record Keeping: establish procedures to keep records of the HACCP system.

Our Clients Says

One stop destination for every legal process 👍🏻👍🏻 5 stars for there service

Nikhat Khan

Their service is appreciated.. good values..

Sonia rani manthapuram

Ready to get started? Contact us!

we help you improve your business through quality management & assurance services.